1. Lub GKG nplooj siab hloov kho jacking platform yog yooj yim, txhim khu kev qha, tsis tshua muaj nqi, thiab yooj yim los kho manually.Nws tuaj yeem kho qhov siab ntawm tus PIN sab saum toj ntawm cov tuab tuab PCB.

2. Cov duab thiab kho qhov muag Qhov system tshiab kho qhov muag - lub teeb lub nplhaib sib xws thiab lub teeb ci siab coaxial, nrog kev ua haujlwm ci ntsa iab uas tuaj yeem hloov kho infinitely, ua rau txhua hom Mark cov ntsiab lus tuaj yeem lees paub zoo (xws li qhov tsis sib xws Mark Point) hloov mus rau tin, tooj liab, kub, tshuaj tsuag tin, FPC thiab lwm yam xim sib txawv ntawm PCB.

3. Scraper system swb-hom scraper system txhawm rau txhim kho kev ua haujlwm ruaj khov thiab ua haujlwm ntev.

4. Kev Tu Cov Txheej Txheem Lub wiper tshiab ua kom muaj kev sib cuag nrog cov stencil, thiab lub tshuab nqus tsev loj loj tuaj yeem lav tias cov tshuaj nplaum uas nyob hauv lub cell yuav raug tshem tawm.Kev ua haujlwm zoo tsis siv neeg tu tau ua tiav: peb hom kev tu lub tshuab nqus tsev ntub thiab qhuav, thiab software yog siv dawb Teem lub hom tu thiab tu daim ntawv ntev.

5. Nthuav steel net kho qauv

6. Zoo meej 2D kuaj pom qhov system

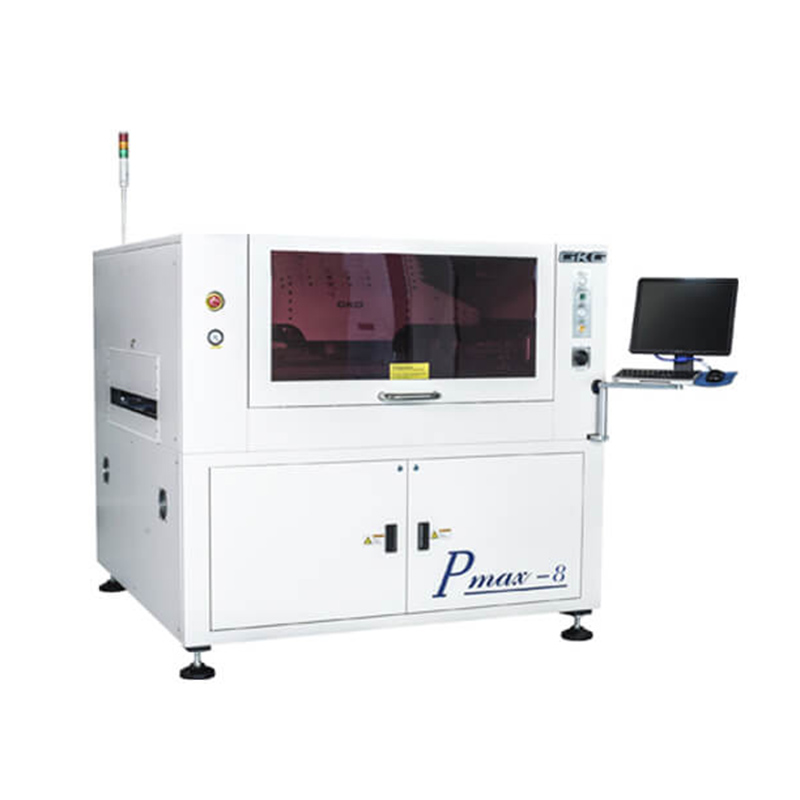

01

Tag nrho cov 3rd tiam tshiab stencil X beam qauv, ntxiv solder paste tswv yooj yim dua thiab raug muab tso rau steel net;

Tshiab hom torque X beam, daws cov solder paste thiab plua plav deposition, ncua lub neej kev pab cuam ntawm lub tshuab;

02

Scalable ntawm cov cuab yeej siab, hauv kev pom ntawm qhov yooj yim deformation ntawm PCB luam ntawv tuaj yeem ua rau cov ntsiav tshuaj tawm, tsis tas yuav siv lub siab me ntsis tuaj yeem rov qab tau dua.Raws li cov khoom siv tau yooj yim siv

03

Lub tshuab tag nrho siv cov khoom siv coj mus muag tus kheej lubricating phau ntawv qhia kev tsheb ciav hlau, qhia kev tsheb ciav hlau tsis tas yuav ntxiv cov roj nplua nyeem, hauv tsib xyoos qhia kev saib xyuas dawb hauv tsib xyoos.

04

X Y1 Y2 hauv Teb Chaws Asmeskas HAYDON linear motor, Japanese precision tsav ntsia hlau, nws tus kheej lubricating qhia kev tsheb nqaj hlau, kom paub tseeb tias qhov tseeb

05

Net thav duab Y kom tau txais qhov chaw, tuaj yeem paub sai sai tsis siv neeg stencil counterpoint;

06

Curved hniav beam siv siab zog steel, nyob rau hauv cov txheej txheem luam ntawv los xyuas kom meej stability ntawm lub taub hau luam ntawv;

Floating type scraper system, lub cim elastic nyob twj ywm, tuaj yeem tiv thaiv zoo heev hauv scraper nco txheej txheem stencil thiab scraper.

Specifications:

| Yam khoom | Parameter | |

| Rov ua qhov tseeb qhov tseeb | ± 0.01mm (Cov ntaub ntawv xeem thiab cov txheej txheem muaj) | |

| Kev luam ntawv raug | ± 0.025mm (Cov ntaub ntawv xeem thiab cov txheej txheem muaj) | |

| Luam Ntawv Ceev / Lub Sij Hawm Lub Sij Hawm | <8s (Tsis suav Luam Ntawv & Tu) | |

| Cov khoom hloov pauv | <5Min | |

| Screen Stencil Loj / Min-Max | 470mm X340mm-737x737mm | |

| Screen Stencil Loj / Thickness | 20mm ~ 40mm | |

| PCB Loj / Min-Max / Thickness | 80X50mm-400x340mm / 0.4 ~ 15mm | |

| PCB Warpage Ratio | <1% (raws li kab pheeb ces kaum) | |

| Hauv qab ntawm Board Loj | 15mm (Standard configuration), 25mm | |

| Ntug ntawm Board Loj | 3mm ib | |

| Conveyor Qhov siab | 900 ± 40 hli | |

| Kev Taw Qhia Conveyor | Sab laug-Rau;Txoj Cai-Sab laug;Sab laug-sab laug;Txoj Cai-Txoj Cai | |

| Conveyor Ceev | 100-1500mm / sec Programmable tswj | |

| Board Positioning | Kev them nyiaj yug System | Sib nqus tus pin / Sab txhawb nqa thaiv / Hloov tsis siv neeg tus pin (yeem) |

| Clamping System | Elastic sab clamping / Nqus nozzle / Extension-hom Z-kev taw qhia rooj teeb | |

| Sau taub hau | Ob qho tib si Motorized printheads | |

| Squeegee Ceev | 6 ~ 300mm / sec | |

| Squeegee Siab | 0-10kg software tswj (kaw-voj siab tawm tswv yim), siab tus nqi pom | |

| Squeegee Angle | 60 ° (Standard) / 55 ° / 45 ° | |

| Squeegee Hom | Steel squeegee (tus qauv), roj hmab squeegee, thiab lwm yam squeegee yuav tsum customized. | |

| Hlau Mesh Sib cais ceev | 0.1 ~ 20mm / sec Programmable Tswj | |

| Txoj kev ntxuav | Qhuav-hom, ntub-hom, nqus-hom (Programmable ua ke ntawm kev ntxuav) | |

| Table Adjustment Range | X: ± 3mm;Y: ± 7mm θ: ± 2 ° | |

| Hom Fiducial Point | Standard geometry duab ntawm fiducial point, bonding ncoo / Stencil qhov | |

| Lub koob yees duab System | Tib lub koob yees duab digital rau upward/downward vision system | |

| Cua Siab | 4 ~ 6Kg / cm2 | |

| Kev siv cua | 0.07 m3 / min | |

| Tswj Txoj Kev | PC tswj | |

| Fais fab mov | AC: 220 ± 10%, 50 / 60HZ 1Φ 1.5KW | |

| Tshuab Dimensions / Nyhav | Nyob ntawm tus qauv raws nraim | |

| Kev ua haujlwm kub | -20 ° C ~ + 45 ° C | |

| Kev khiav dej num | 30% ~ 60% | |